Home

Explore our farm solutions

Milking

DeLaval VMS™ Series

Your VMS™. Your Way.

With DeLaval VMS Series it all revolves around you

We have developed VMS from the V300 series to be the world’s most flexible milking robots – so that they work for you, and not the other way around.

A milking robot from the VMS V300 series offers the best milking process we have ever created, maximizing the economic benefit of every visit your cows make to it. It allows each cow to be milked to her individual needs and capacity, meaning each cow reaches their full potential.

Key features of the VMS V300 series

Which VMS is right for you?

We have different options in our milking robot series to help you get the maximum potential. Which robot suits you best?

DeLaval VMS™ V300

The DeLaval VMS Series gives you options to create the milking system that best matches your needs and farming style. Both the VMS V300 and VMS V310 feature the core functionality that ensures your cows are milked to their full potential.

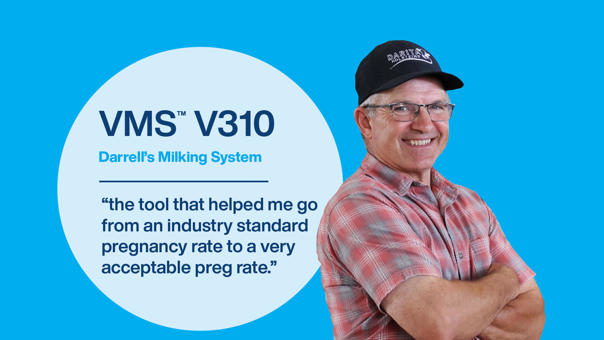

DeLaval VMS™ V310

With the VMS V310 that productivity advantage is extended to the next generation of cows as well, with Progesterone based sampling and analysis adding full pregnancy and heat detection to the list of tasks these amazing systems can complete automatically.

Farm Your Way

Batch or voluntary, 24/7 or twice a day, pasture or barn; you decide. It’s your farm and only you know what works best for your conditions and your animals.

Simple, open design

Free traffic

If you have the labor handy to fetch cows, a free traffic system is good for retro-fits and freedom of cows. Our planning teams will assist you to meet robot performance goals by balancing robot pellets with PMR and guidance on the specific layout for post-sort options.

Milk first or modified

Guided traffic

Reduce the cow fetching schlep with a guided traffic system. DeLaval’s advisory and planning teams will assist you to retrofit and/or new build your barn to optimize VMS, whether with gates to direct traffic to VMS or feed and great post-sort options.

The main benefits: the VMS V300 Series delivers more

Milking robots from the VMS V300 series are designed to deliver more, better quality milk, healthier animals, and more freedom for you.

Farm Profitability

Our system is designed to help you generate more milk, more efficiently, more safely and more sustainably, in a way that also meets the consumer pressures that farmers the world over are facing today.

- Lower your use of energy, water, teat spray, labor and vet costs.

- Lower cull rate and a real possibility of more lactations per cow.

- Permission-based milking means an optimum yield per milking.

Animal Welfare

As a pure Voluntary Milking System, VMS™ is not a conveyor belt that treats cows like products, it is a fully automated milking system that helps generate better results for you and your animals.

- Happy, healthy and calm cows produce more milk and live longer.

- Get a possible extra lactation of out of cows.

- Avoid mastitis and achieve low cell count.

Work Efficiency

The VMS™ V300 Series is all about doing more with less - creating a better work environment and lifestyle for you and anyone who works on your farm.

- Increase milk production per labor hour.

- Automate as many repetitive manual tasks as possible and focus on high value tasks.

- Schedule tasks on your terms.

- Attract and retain quality staff.

Service your way

Maximize the performance of your automated milking system with a Performance Plan

DeLaval DelPro™

Make better decisions with accurate and timely analysis and predictions.

DeLaval DelPro™ FarmManager helps you bundle, process and analyze the many data sources on your farm. This allows us to generate valuable information and reports that help with your management.

InService

You decide what you want to include:

- Scheduled servicing and maintenance

- Emergency callouts

- Advisory Services

- Consumables

- Settings, routines, training and optimization

Advisory

Achieve your goals with advice and support.

Our advisors will help you with advice before, during and long after the installation of your DeLaval milk system. They provide support in further optimizing the performance of your installation. Together with you, they can ensure that the results of the milk system are tailored to your needs and circumstances.

Works well with the wider DeLaval Ecosystem

From cooling, storing and transporting down to feeding and hygiene products, the VMS™ works together with all parts of the DeLaval ecosystem.

Dairy producer testimonials reflect their real-life experience using DeLaval products. Results in testimonials have not been independently verified and DeLaval does not claim the results are typical. Actual performance and improvement will depend on a number of factors, including prior milking practices, type of cows, farm and herd maintenance practices. Testimonials do not constitute warranties or guaranties of service or performance.